How to cool a factory without spending a fortune

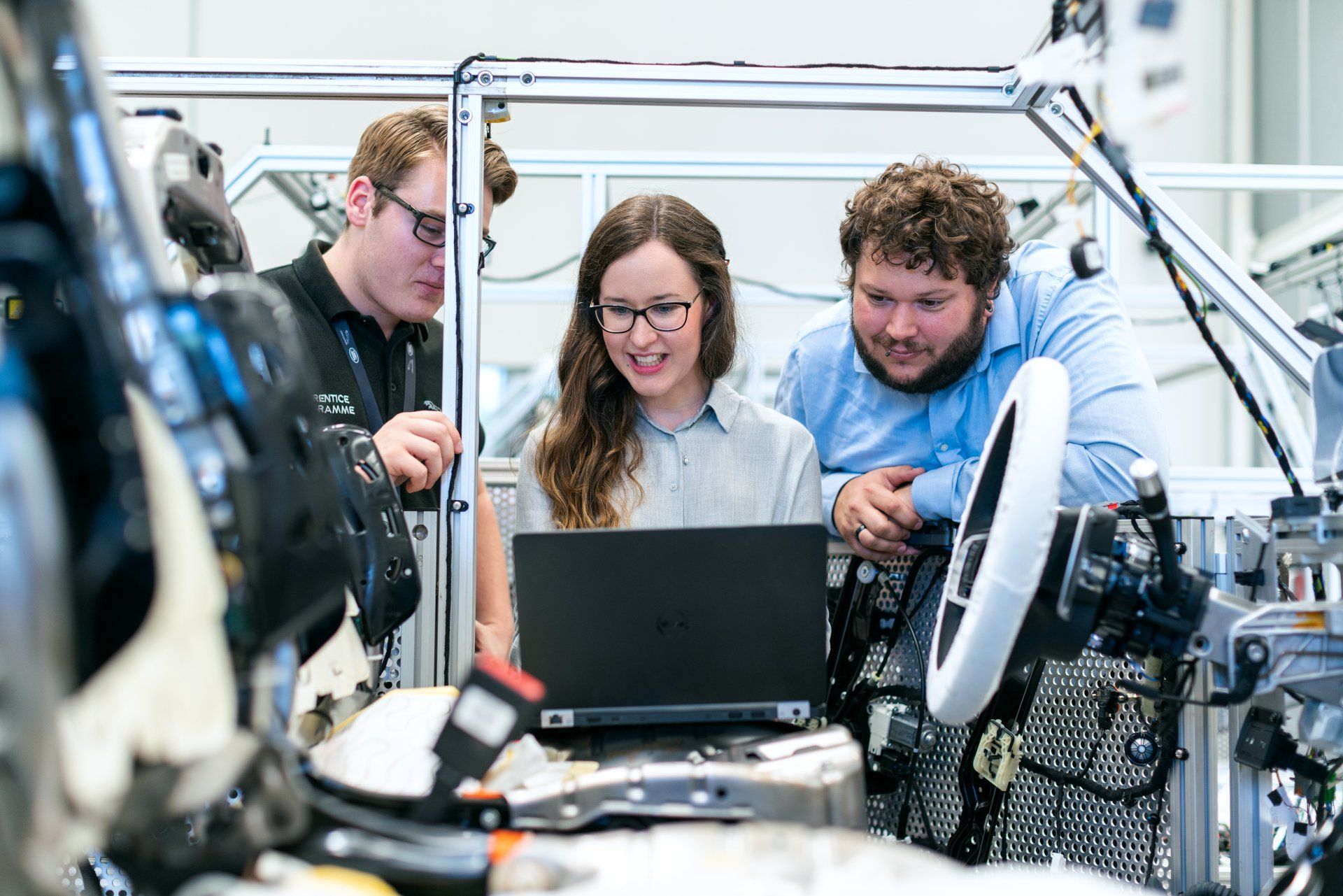

Factory cooling is a big deal. A large interior space isn’t necessarily prone to overheating per se, but when you add moving parts and production lines to the equation, things can soon get too hot for human comfort. When the temperature outdoors keeps on rising, components and products can suffer and production lines can start to struggle.

In a world where the climate is heating up fast, how do you achieve effective low-energy cooling for your factory floor, whether it’s a new build or an existing building?

A complex cooling challenge for a large factory

Imagine you’re an international supplier of precision machine components with a great reputation to maintain and a target market where high quality and fast reaction times absolutely essential. You’ve built the business on meeting customer needs perfectly every time. Maybe you run a print works where the industrial printing equipment itself generates vast amounts of heat, leaving people unable to work comfortably in our hotter springs and summers. Or a bakery where intense heat can affect the ingredients as well as disturb the natural processes needed to create beautiful baked goods.

In the past the heat generated from the production process and the people operating machines and lines was easier to handle. But with outdoor temperatures soaring to heatwave levels more often than ever, you need to manage the temperature indoors so conditions are comfortable for workers and visitors whatever the weather.

When ordinary aircon isn’t man enough for the job

Ordinary air conditioning-style cooling can prove challenging and expensive when there’s an enormous open space to keep cool. Add a large number of employees working on the shop floor, plus heat-generating machinery, and the solution clearly needs to be man enough for the job. You want to keep intensive machine-generated manufacturing areas cool as well as keeping people fresh, lively and alert.

When you also want to meet government legislation around reducing emissions and bring better corporate social responsibility to the party, a workable solution can seem like a big ask. Luckily evaporative cooling ticks all the boxes.

Innovative, low cost evaporative cooling

The best way to cope with the extra heat you’ve started seeing in spring and summer turns out to be eco-cooling, a system that’s surprisingly simple as well as extremely cost effective to run. It’s affordable in the first place, it cools factory floors efficiently, can be zoned to suit different areas, costs very little to run, and can easily scale up as the company grows.

Imagine you’ve had the perfect evaporative cooling system designed specifically for your factory. It has been specified and fitted by an experienced installer who first carried out a detailed survey of the facility to pin down the ideal number of units, ensure the correct airflow and deliver optimum performance.

The new system gives you complete control of the air temperature and humidity levels in assembly and manufacturing machine areas. You enjoy reliable, refreshing cooling via evaporation and fresh air during summer, when clean cool air is ducted into the premises through acoustic lined flexible ducting and four-way diffuser grilles. In winter the system re-circulates fresh air. The conditions indoors are comfortable for employees even on the hottest days and your production lines run smoothly whatever the weather.

Evaporative cooling systems deliver massive energy savings

The energy savings you get from your fully controllable evaporative cooling solution are significant, clocking up just 10% of the energy used by traditional air conditioning. The eco-benefits are just as significant bearing in mind a single EcoCooler, rated at 35kW, can deliver CO2 savings of up to 10,000kg a year.

A perfectly natural way to produce refreshing cool air, your evaporative cooling systems future-proofs the premises and the business while your competitors are having a hard time coping with ever-more frequent heatwaves.

It costs nothing to talk

Would you like to discuss the potential of low cost, low energy, high efficiency cooling with an expert? We’re always glad to talk things through and while a discussion won’t cost you a penny, an evaporative cooling system could save you a fortune.